Glaston CNC96 Upgrade Kit Extends Machinery Lifetime

Glaston has introduced its CNC96 upgrade kit for automotive and architectural glass-cutting equipment. This enhances the CNC96 control system while modernising any components at the end of their life. It is part of the company’s larger lifecycle support offering to keep customers’ machinery operating at peak performance.

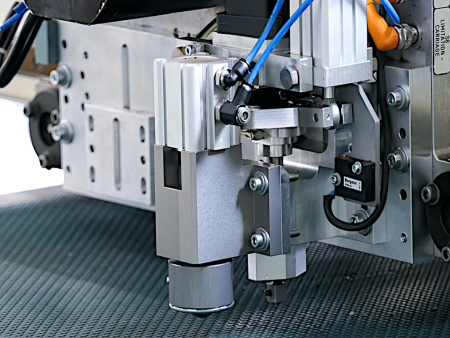

Glaston’s CNC96 was first released in 1996 as an in-house system engineered with exclusively developed hardware components. Over the years, this system has helped processors attain outstanding precision with their edge cutting, breaking, grinding, drilling, and other critical functions for high-quality automotive and architectural glass.

“As we approach 2025, certain control components of the CNC96 are coming to the end of their life,” says Artturi Mäki, Senior Vice President of Services at Glaston. “Therefore, we have developed a cost-effective CNC96 upgrade kit to guarantee continued machine performance with a considerable extension of the CNC96 system lifetime. This retrofit is just one of our wide range of upgrades that allow you to get the most from your machinery and prove that your investment is safe with us.”

Glaston’s release of the CNC96 upgrade kit is a proactive step to extend the lifetime of the processing equipment and ensure uninterrupted performance. This solution is designed to fit the solid mechanically engineered lines to deliver up to an additional 10 years of dependable operation. As the original equipment manufacturer (OEM), Glaston provides comprehensive support and ensures the continued long-term availability of spares.