In 2020–2021 Zippe Industrieanlagen received orders from European container glass producers for the latest generation of batch and cullet preheaters. These resulted in the successful commissioning of two ABPneo batch and cullet preheating systems in just one month. The new ABP version (Advanced Batch preheater) ABPneo integrates several new features, especially a highly efficient de-vaporisation unit as well as general high operation stability. “The ABPneo shows that our developments of the last years proved to be successful and we are happy to offer and realise these with our customers,” says Volker Maier, Head of Sales.

Austria

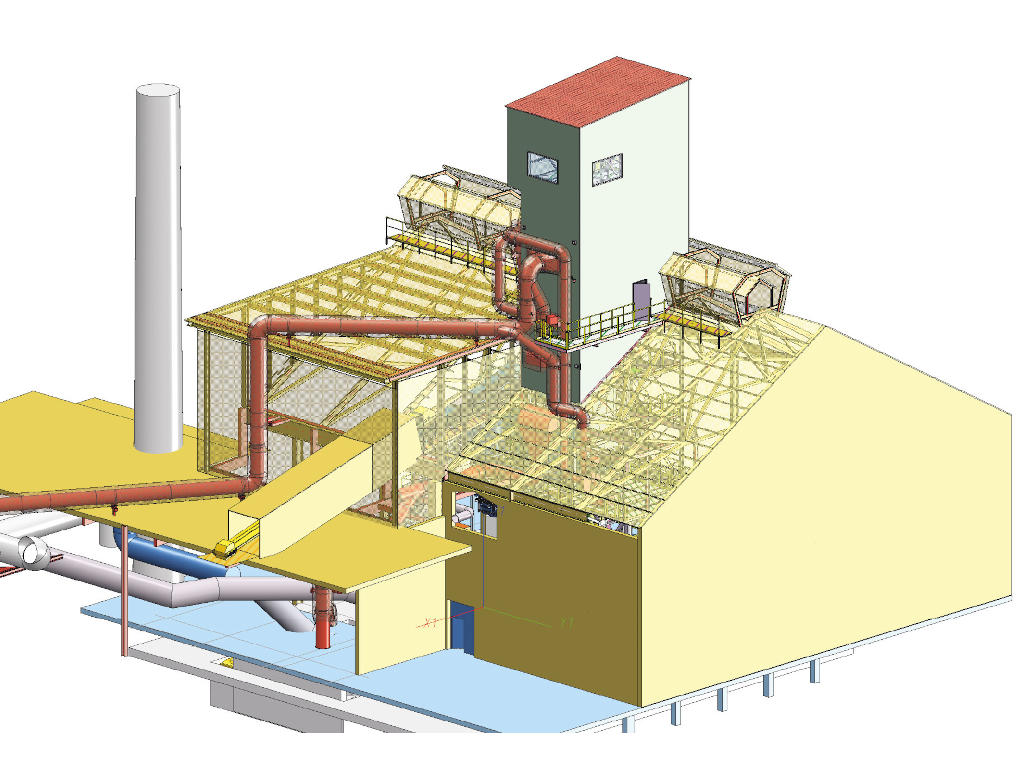

One project was realised in Austria and involved Zippe’s new generation ABPneo batch and cullet preheater for a regenerative melting furnace producing coloured container glass. Fired with natural gas, the furnace’s average output is 130tpd. Using exhaust gases with a temperature of approx. 460°C it is possible to heat up batch and cullet to approx. 180–200°C. Through this process, the customer saves a significant amount of energy and related costs. The proportion of cullet is 60–70%.

The preheater was retrofitted to a regenerative furnace with one doghouse. Close co-operation with the customer was very important to ensure a smooth integration and commissioning. The rebuild was achieved by modifying the batch transport system during ongoing operation within a very short timeframe. The customer was very satisfied with the close co-operation during this phase, and Zippe is pleased to be able to support this customer in reducing their CO2 emissions and energy consumption.

Germany

Another ABPneo batch and cullet preheater was commissioned in Germany on behalf of a major European container glass producer. Here too, the batch transport, the furnace silo area and the batch charging system were part of a major refurbishment. To ensure efficient batch charging of an enclosed doghouse situation, Zippe installed its new Vibrotube Charger to enhance the energy balance. Exhaust gases with a temperature of 480°C are used to preheat the batch and cullet to values above 200°C and in this instance the proportion of cullet glass is 70–80%.

The preheater was installed at one doghouse at a regenerative furnace which is equipped with two doghouses. The second doghouse is kept as a standby unit.

Commissioning and installation were achieved during operation of the new furnace and first results show significant reductions of natural gas consumption.

A batch and cullet preheater can be planned as an integrated element of batch processing, but also as a retrofit at a later point of time.

As a pioneer of this technology, Zippe continues to refine its capabilities to offer customers the most advanced systems to help reduce melting costs and emissions and increase energy efficiency and plant productivity.

ABPneo Batch and Cullet Preheater and Vibrotube Charger are registered trademarks of Zippe.

Image: A 3D model of the project in Austria.